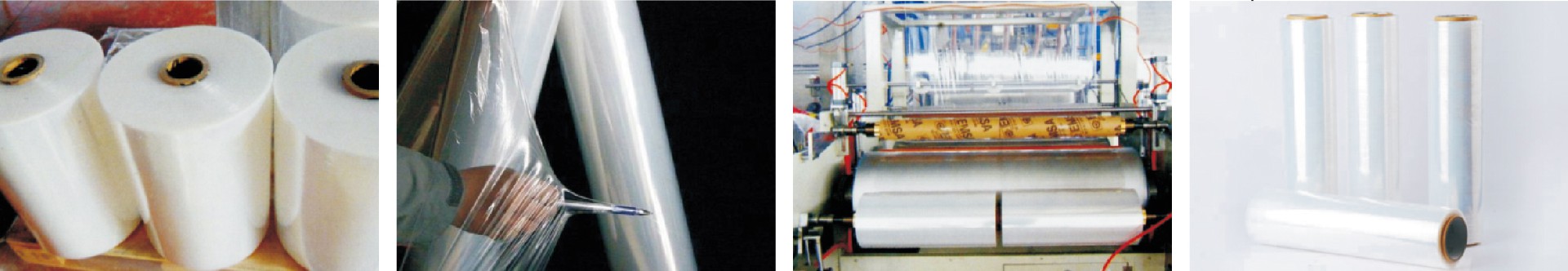

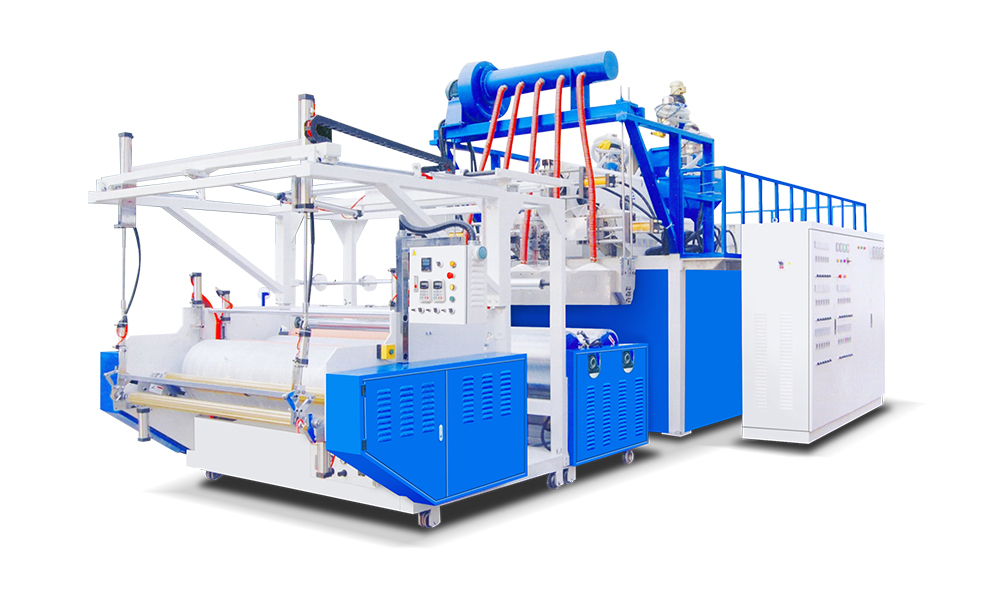

New type high speed fully automatic 2 layer /3 layer co-extrusion stretch film machine

2021-08-27 10:08:59 source:本站

Detailed introduction

Mainly suitable for the production of LLDPE, LDPE, PE, CPE, PEVA and other flow film,   The unit adopts advanced intelligent industrial control system, with hidden automatic cutting knife, automatic cutting, automatic mechanical hand automatic rewinding, automatic loading and unloading paper tube device, to ensure that the operation is safe and convenient, winding more solid, smooth, to ensure the quality of products. Greatly improve the production efficiency, reduce the production cost, create greater value. The swing device can improve the flatness and appearance quality of the coil and make the product more competitive.

Features

·The alloys crew adopts special mixing function and high plastic izing performance design which combines the imported static mixer to ensure the good plastic ization, uniform color and great increase in the extruding capacity.

·The T-die is made of imported high quality mould steel which is processed by high accuracy treatment it preventsf heT-die from deformation in longtime usage and the casting is smoother and more stable.

·The design inside the cooling roller Is bi-directional and in circuit.The roller is with built-inspiral runner whichensures the even surface temperature.

·The winding staion can move back and forth.t adopts advanced torque motor which can adjust the speed and the width of the film freely.

Ptional system

➊Vacuum box system (vacuumizing)

❷Melting gear pump and PID controlling system

❸Micro-computer temperature controller with touch screen for accurate temperature control

❹Automatic air shaft loading

❺Automatic screen changer with hydraulic station

Technical parameters

型号 | Model | PB-LΦ55/75×1250 |

螺杆直径 | Screw Diameter | 55/75mm |

螺杆长径比 | Screw L/D | 30:1 |

螺杆转速 | Screw Speed | 50-150rpm |

制品宽度 | Width | 1000mm(2×500mm) |

总功率 | Toral Power | 75kw |

产品厚度 | Thickness | 0.01-0.05mm |

生产能力 | Caoacity | 80-150kg/h |

膜层结构 | Layer Structure | AB/ABA |

整体重量 | Total Weight | 8T |

外形尺寸(mm) | Dimension(mm) | (L)7500×(W)3000×(H)3400 |